When planning a vacation or even an everyday event, we may not think about lightning. However, lightning occurs at a rate of about 100 times each second.1 A single lightning strike contains over 1 million volts of electricity causing potential for destruction internally and externally to a building. We come to associate lightning strikes with fires and structural damage, since these are the visual icons used to show the damage from lightning. The internal damage from lightning can be greater than the external damage. When this immense energy hits a structure, the power surges through the pipes, the building structure, and electrical infrastructure. From the typical to the extremes, buildings and structures can avoid these damages with the proper design and installation of a lightning protection system.

Photo courtesy of The Lightning Protection Institute.

Whether you are a fun seeker in the mountains of Colorado or the beaches of Florida, you can be assured that you are protected from lightning in both locations – at least at these two venues. Pikes Peak Visitor Center is at the summit of Pikes Peak with extreme weather conditions including hurricane-force winds, air temperatures recorded as low as -39 degrees Fahrenheit, and a propensity for thunderstorms and thundersnows.

The Hard Rock Hotel & Casino showcases a modern and unique design that resides in a region with one of the greatest lightning densities in North America. The lightning-related risks are also increased due to the building’s height and size, and the potential difficulty of evacuating sleeping guests and the large crowds in the casino and at special events.

These extreme climates and structures create a challenge for all involved in the design and installation of a lightning protection system.

When the design/build community comes together with lightning protection experts, the results are buildings and communities that are protected.

Building to the Extremes starts with the Basics

Understanding the components and the basics of a lightning protection system process enable everyone to make the appropriate assessment and recommendations for a design.

From modern high rises to historical buildings, the process remains the same. However, the variations in structural design and building materials require early planning and collaboration among the trades so everyone’s installation and project meets codes and expectations.

The “process” includes five main steps:

- Assessment

- Specification

- Installation

- Inspection/Certification

- Maintenance

The “Components” of a Lightning Protection System

This basic knowledge is the starting point for proper assessment and considerations for the specification: building materials, special architectural features, rooftop equipment and more.

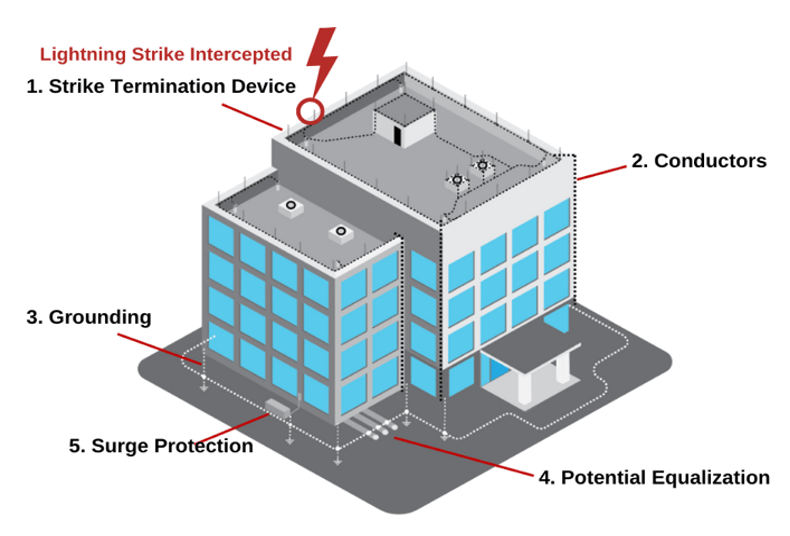

Lightning protection systems are composed of five components that have precise materials, sizes, and installation measurements.

1. Strike Termination Devices: air terminals, (informally known as lightning rods) on high points of a building intercept lightning strikes.

2. Conductors: heavy-duty metal cables connect the parts of a lightning protection.

3. Bonding: conductors are also used to equalize electrical potential throughout a building to prevent lightning from creating dangerous electrical arcing or side flashes.

4. Grounding Electrodes: most buildings can be grounded with 10-ft-long, copper-clad steel rods driven into the earth at multiple points around a building.

5. Surge Protection: special surge protective devices must be installed wherever power or signal wires enter a building to prevent excessive electrical surges from causing damage. The surge protectors built into appliances and power strips do not protect against powerful lightning surges.

Although not part of the system, the final step in this process should always be inspection and certification by a third party to ensure that all standards for design and installation have been followed.

When these components are properly designed and installed, a lightning strike is intercepted by the strike determination device and directed to the ground without impact to the structure or the electronic infrastructure.

Image courtesy of The Lightning Protection Institute.

Collaborating for the Extreme

All projects should start with an assessment. The NFPA 780 outlines a simple assessment that encompasses gathering data points from the location of the structure to the contents and use of that building. In conjunction with the NFPA 780, certified lightning protection experts can be utilized to lead the way.

During this assessment, asking questions from the various experts and building management can ensure a more thorough specification and decrease the chances of mistakes or delays in the entire building project.

Are there certain design elements of the building that are important?

Are there special materials being used for coping, flashing, structural railings?

Do the building enclosure experts anticipate any challenges?

A thorough assessment will lead to a detailed specification to ensure that all aspects of the lightning protection system follow the strict guidelines outlined in the NFPA 7802 and LPI1753.

Assessment and a well-defined specification are key to any project. When it comes to extreme projects or those that require special attention to aesthetics, collaboration becomes even more important. Early collaboration can enable architects and general contractors to plan for the concealment of the system within the internal walls. In addition, alternative material choices can be made and building components can be configured as strike termination devices for the system.

Both the Hard Rock Hotel & Casino and the Pikes Peak Summit Visitor Center sourced several experts in the assessment process which resulted in thoughtful consideration to integrating the system into walls and/or utilizing architectural elements as part of the system.

Extreme Design

Modern and Uniquely Shaped Buildings

The Hard Rock’s signature guitar shape of the building made the design and installation of its lightning protection system challenging.

Due to the complex geometry of the building, there was constant coordination among the building’s architect, engineers, curtainwall fabricator, curtainwall installer, general contractor, and lightning protection system contractor in regard to details, schedule and access.

A rolling sphere analysis was used to determine the zone of protection for this uniquely designed hotel. This analysis determined that the curved sidewalls had potential lightning attachment points, areas that would be more susceptible to a lightning strike. This required the installation of air terminals on the aluminum and glass curtainwall.

Hard Rock Hotel & Casino; Hollywood, Fla. Photo courtesy of Pixabay.

Close Coordination with Curtainwall Fabricators

Close collaboration with the curtainwall fabricator and installer was required to provide mounting brackets on the curtainwall, especially because the inclination of air terminals varied depending on the curved wall’s changing tangent.

Photos courtesy of Bonded Lightning Protection Solutions.

Similarly, the size and construction of each floor plate varied, and each level required different details for attaching cables from the curtainwall to down conductors. At some locations, air terminals could be installed from the interior as glazing progressed.

Photos courtesy of Bonded Lightning Protection Solutions.

Extreme Climate Mountain Top Visitor Center

Pikes Peak Summit Visitor Center is an excellent example of early coordination of people, processes, and materials. Input from several different fields and thorough assessment of the natural landscape, climate and building usage, lead to a design that is architecturally stunning and safe from lightning.

The building is at the summit of Pikes Peak at an altitude of 14,115 feet above sea level. Working at this elevation required extraordinary attention to the health and safety of the work force. The number of hours that an individual was permitted to work at elevation was limited, adequate hydration was promoted, and health monitoring programs were in place to identify individuals in distress.

The extreme temperatures, hurricane-force winds, and low soil conductivity created several challenges for the project team.

Photo 1: Pikes Peak Visitor Center; Boulder, Co. Photo courtesy of RTA Architects; Boulder, Co.

Photo 2: Photo courtesy of Mr. Lightning.

Photo 3: At rooftop terraces, conductor cables were covered with concrete topping slabs. Vertical threaded rods were attached to metal railings that serve as strike termination devices. Photo courtesy of Mr. Lightning.

Exposed elements of the structure had to be hardened to withstand conditions. For example, exposed conductor cables were avoided wherever practical, air terminals bases were provided with extra-strong attachment to structure, and through-structure penetrations were minimized. Permanent metal fabrications—including railings and roof gutters made from steel plate—were used as strike termination devices and in lieu of conductor cables.

All parties involved in the design process wanted a building that would honor the legacy of the Summit House yet not overwhelm the spectacular beauty of the mountaintop or the vistas that visitors experience. This goal influenced the design of the lightning protection system and the selection of materials used.

Photo 1: No through-roof penetrations were allowed on the standing seam roof. At the perimeter of the roof, a custom gutter and coping is made of steel plate to resist the harsh weather conditions and to be electrically continuous with the air terminals. Photo courtesy of Mr. Lightning.

Photo 2: Railings, made of weathering steel, are electrically continuous with the lightning protection system and used as strike termination devices. Photo courtesy of Mr. Lightning.

Photo 3: Portions of the rooftop terrace are covered with stone to look like the natural mountaintop. The air terminals installed on the rock are made of copper to better match the rock. Photo courtesy of Mr. Lightning.

Early Collaboration for Design and Function

With the frequency and potential of destruction, lightning deserves our attention. The damage of hurricanes, floods, and fires gains significant media exposure, so we can understand the impact and be prepared. Lightning is just as powerful and should be understood.

The design/build community continues to find ways to innovate design and materials to increase the safety level for individuals and communities. Fire alarms are now standard practice to mitigate risks to individuals and minimize the structural damage caused by a fire. Buildings can be designed to tolerate earthquakes. And over the last decade, new materials and design methods have been utilized and tested to build hurricane resilient homes. These life safety measures are due to the collaboration of trades.

Lightning protection systems are scientifically proven to mitigate risks. All of us, as experts in our fields, have the opportunity to protect the welfare of the community with a clear understanding of these systems. Through collaboration, we can create practical and extreme designs that ensure that people are protected from lightning, and the function of building is maintained.