Photo courtesy of Getty Images.

FEATURE

Navigating Fenestration U-Factors

Properly Calculating Fenestration U-Factors is Important to Building Enclosure Design

By Mary C. Arntzen, P.E. and Scott A. Tomlinson, P.E.

The building code provides requirements for energy performance of window and other fenestration assemblies, including the maximum allowable fenestration U-factors. It can be challenging for designers to meet the U-factor requirements, when working on new and existing buildings. Understanding the energy code requirements and how to properly calculate the fenestration U-factors is an important skill to develop to inform the building-enclosure design. This article provides a review of fenestration U-factors, related code requirements, an example calculation, and other practical considerations for understanding U-factors.

What is a Fenestration U-Factor

The International Energy Conservation Code (IECC, 2018 referenced herein) defines U-factor (thermal transmittance) as “the coefficient of heat transmission (air to air) through a building component or assembly, equal to the time rate of heat flow per unit area and unit temperature difference between the warm side and cold side air films [(Btu/h • ft2 • °F) [W/(m2 • K)].” In other words, a U-factor defines the rate of heat loss through a component or assembly. U-factor is the reciprocal R-value, so a lower U-factor means greater resistance to heat flow and improved thermal performance.

Fenestration

U-factor ratings are generally determined in accordance with National Fenestration Rating Council (NFRC) 100 “Procedure for Determining Fenestration Product U-factors.” NFRC 100 requires computer simulations to determine the U-factor of fenestration products. It requires physical testing to validate baseline product simulations, when baseline product simulations cannot be validated (simulated and tested U-factors for the baseline product are not equivalent), or when simulations cannot be performed in accordance with the standard. Simulations and physical testing exclude perimeter conditions to limit heat transfer to the fenestration product only. Therefore, designed and constructed perimeter conditions, such as the position of the fenestration thermal break relative to exterior building wall insulation plane, some perimeter flanges, and other elements that create thermal bridges, can significantly affect in-situ fenestration-perimeter interface thermal performance.

Reporting of Fenestration U-Factors

Fenestration manufacturers often report the total product U-factors (combined frame and glazing) based on different glazing options (glazing U-factors). The reported total product U-factor is typically based on NFRC standard model (specimen) size, which varies by product type (e.g., curtain wall is different than a casement window). The model size impacts performance, as discussed in more detail below.

Insulating glass unit (IGU) manufacturers report the overall, center-of-glass (COG), and edge-of-glass (EOG) U-factors for the IGU. The overall IGU U-factor can be determined using the EOG and COG values and will be affected by the IGU make-up, including spacer type, IGU gas fill type, coatings, overall thickness, etc.

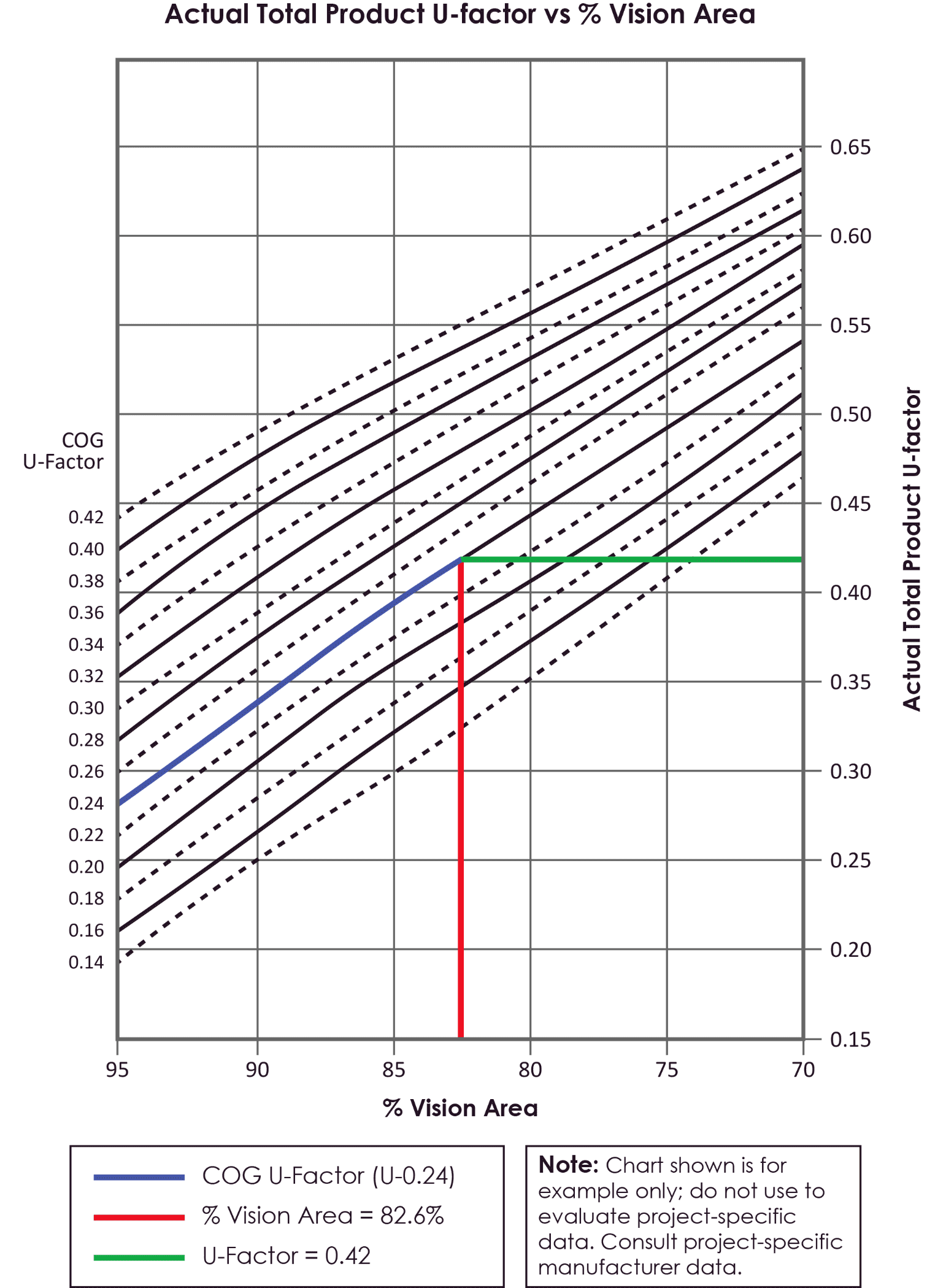

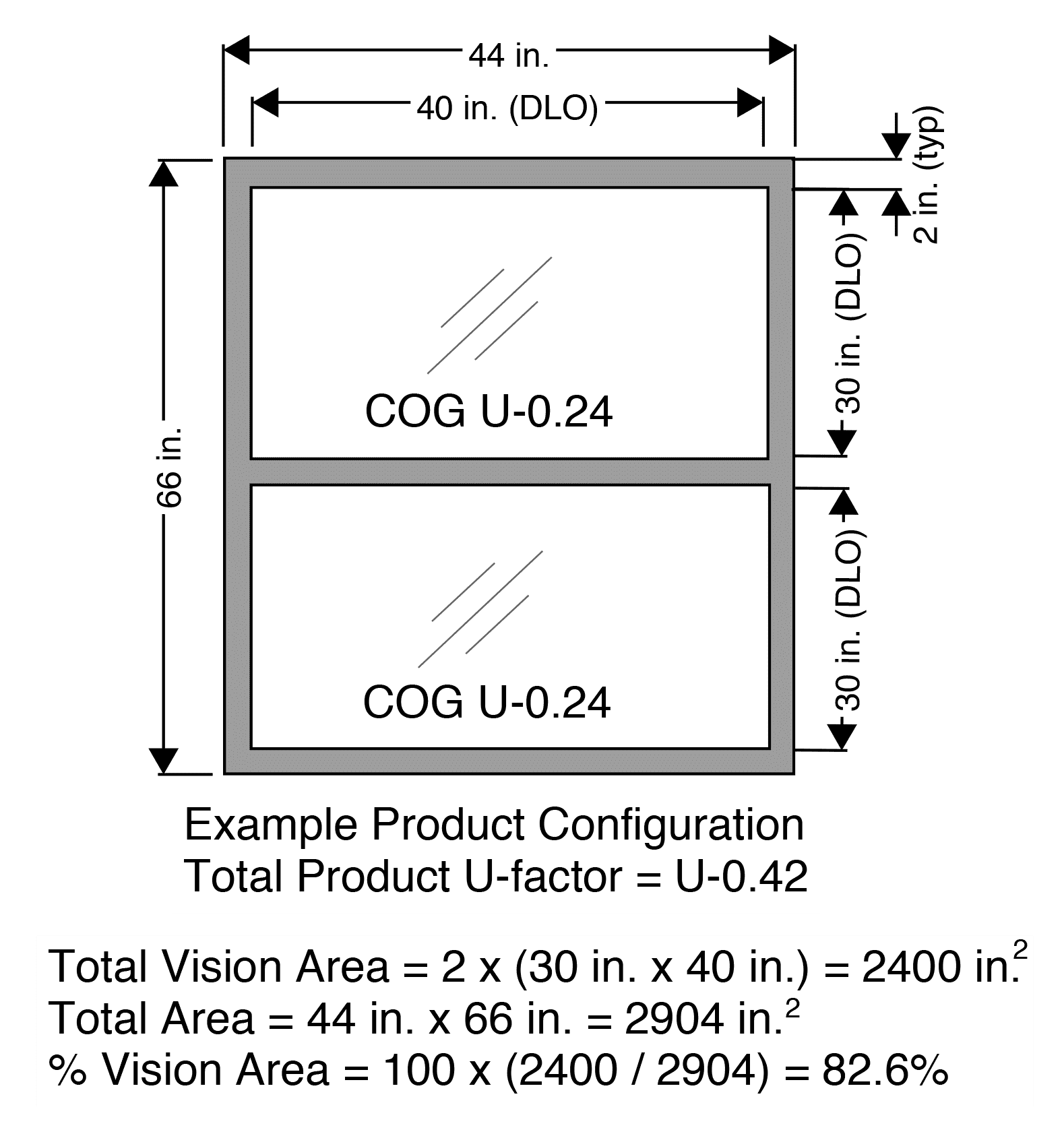

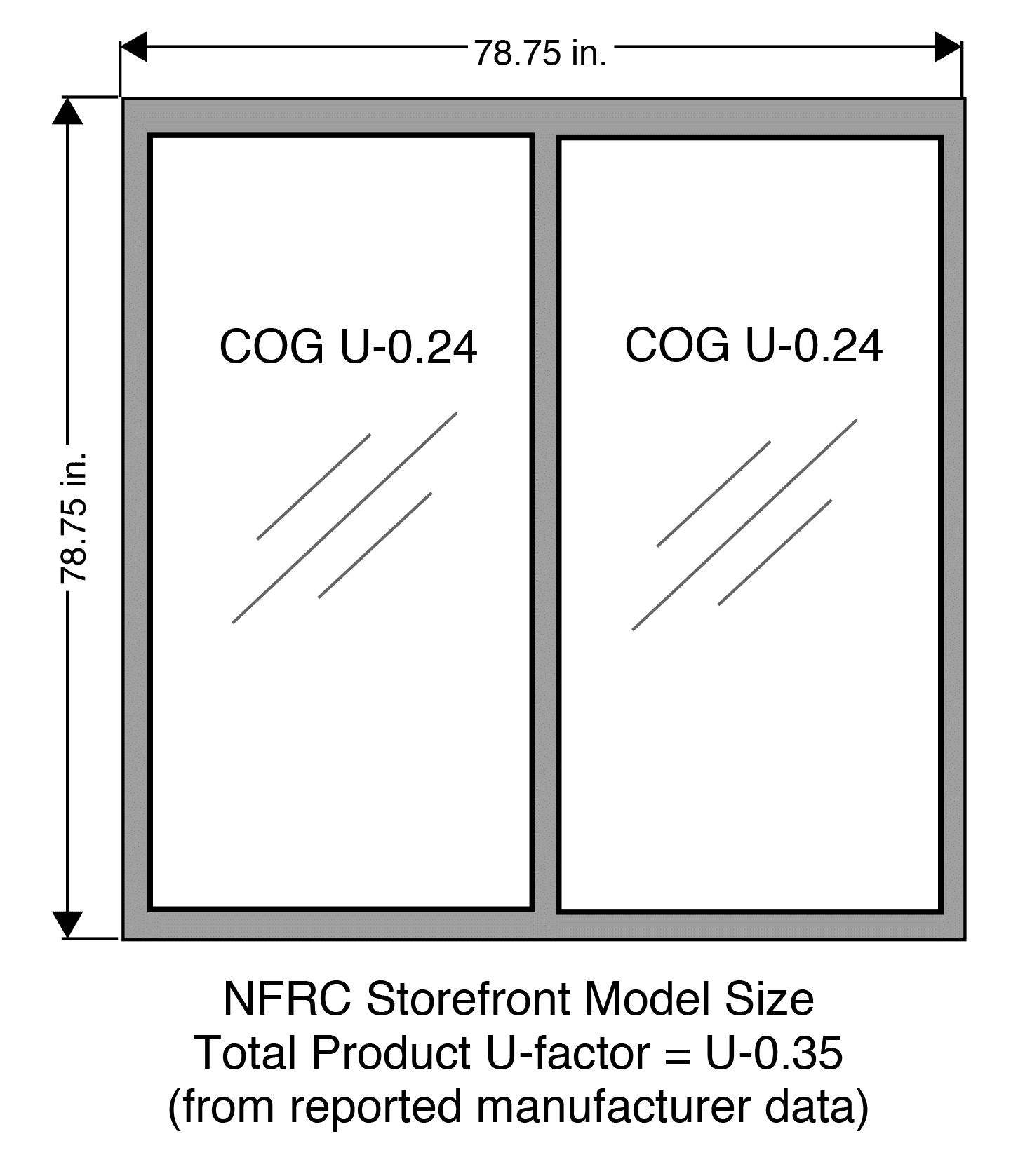

Fenestration product size affects performance. For example, a larger glass/aluminum curtain wall/window wall/storefront/sloped glazing (one NFRC 100 product type) assembly with an IGU can have a notably lower total product U-factor (i.e., improved thermal performance) compared to the same assembly that is smaller. This is because the IGU EOG and fenestration framing generally exhibit higher heat transfer (i.e., lower thermal performance) compared to the IGU COG. Therefore, as the percent glazing area of the fenestration decreases, the U-factor of the assembly generally increases. The NFRC standard model size for a storefront product type is 78.75 inches by 78.75 inches with one intermediate vertical mullion, which is a relatively large fenestration. This means the actual size used on many projects may be smaller or include more intermediate framing than the NFRC standard model size and have a higher U-factor (i.e., lower thermal performance) than reported by the manufacturer.

Many fenestration product manufacturers only report the total product U-factor for the NFRC standard model size. However, fenestration manufacturers typically can provide charts, when requested, to compare the COG U-factor against the project specific percent vision area to determine the total product U-factor for sizes other than the NFRC standard model size.

" Understanding fenestration U-factor, energy code requirements, and how to properly calculate project specific total product fenestration U-factors for are important to inform a project design... "

FIGURE 1B - Example storefront product size and configuration.

FIGURE 1A - NFRC standard model size and configuration for a storefront unit.

Energy Code Requirements for Fenestration U-factors

The IECC generally governs building-energy-performance requirements, which can be further amended by the local authority having jurisdiction. The IECC provides fenestration U-factor requirements and allows the use of prescriptive and performance compliance methods. Using the prescriptive method to determine fenestration U-factor compliance means that the designer must confirm that the U-factor for each fenestration assembly is equal to or less than the prescribed maximum value, with a few exceptions. The performance compliance method provides for a more holistic whole-building energy analysis, though some jurisdictions require maximum U-factors for assemblies even when incorporating a whole-building analysis.

The design of new buildings or additions often utilize the performance compliance method. Even with the performance compliance method, designers may still check basis-of-design fenestration U-factors against prescriptive requirements early in the design process. This cursory check allows the designer to evaluate the anticipated performance of the schematic design, particularly in jurisdictions, where codes require minimum overall building-enclosure performance. If issues are

identified during this process, the designer can modify the design to meet performance requirements.

The design of fenestration replacement in existing buildings often utilizes the prescriptive compliance method. Meeting fenestration U-factor requirements using the prescriptive method can be more challenging, particularly when replacing fenestrations in older buildings that were not designed with modern energy performance requirements in mind, and where opening sizes and fenestration appearance likely cannot be easily modified.

The IECC (subsection C401.2.1) recognizes this challenge by allowing the use of an area-weighted average to meet prescriptive requirements for replacement fenestration products; application of this method is beyond the scope of this article. When applying the prescriptive code to replacement products, the designer is generally required to consider operable and fixed windows and entrance doors separately because each product category has different U-factor requirements. Spandrel areas are sometimes considered part of the opaque wall area.

Figure 2 – Example of charts that may be published by manufacturers to determine actual total product U-factor based on percent vision area and COG U-factor.