By their very nature, all building foundations touch the earth that surrounds them. In every climate, the water, air, soil, and temperature of that outside contact can impact the performance and integrity of the entire building structure. A variety of insulation products and water-resistant surface treatments are available to mitigate moisture problems with below-grade walls.

Polyiso

Polyisocyanurate (“polyiso”) boards are some of the most popular insulation products on the market today. Made of water resistant rigid foam sandwiched between two protective facers, polyiso insulation is commonly used on commercial and residential roofs and walls because of its high R-value per inch of thickness, its capacity to serve as a vapor retarder, low water absorption, high compressive strength and durability, and ease of handling.

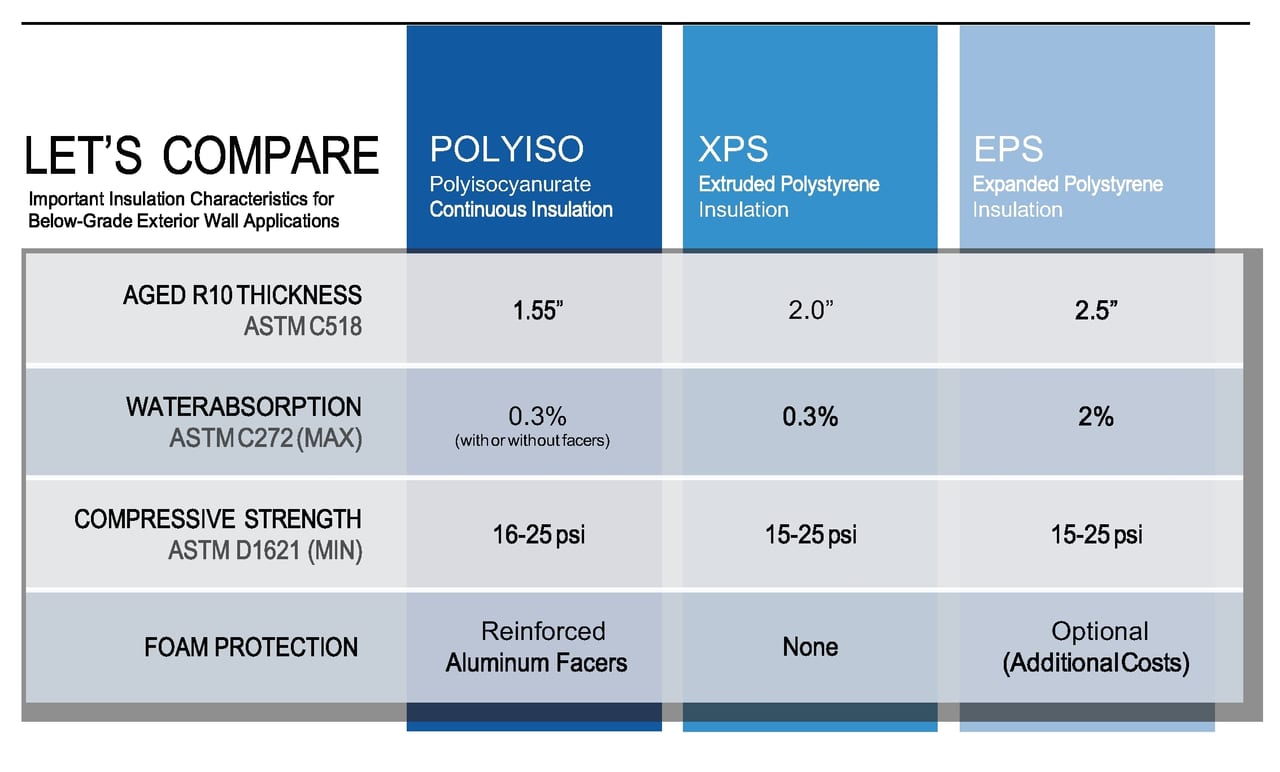

What many builders don’t realize is that, depending on facer type used, polyiso can also be used in below-grade applications in both commercial and residential buildings to protect basement and foundation walls. A common misconception in the construction field is that polyiso is not suited for use below-grade because it is frequently produced with all paper facers that can absorb moisture. Some builders turn instead to other products like extruded polystyrene (XPS) or expanded (EPS) polystyrene that require more material to achieve the same R-value. Polyiso, which is itself water resistant because of its closed cell structure, is also sold with durable, non-absorbing facers—aluminum foil facers and coated glass facers—that are appropriate for moist environments such as below-grade applications.

Scaffolding and facade of an office building under construction where insulation has been applied. Photo courtesy of Getty Images; EThamPhoto.

"Though most builders think of polyiso as a product used in low-slope roofs, its excellent performance has expanded its market share in applications on roofs and walls of all kinds..."

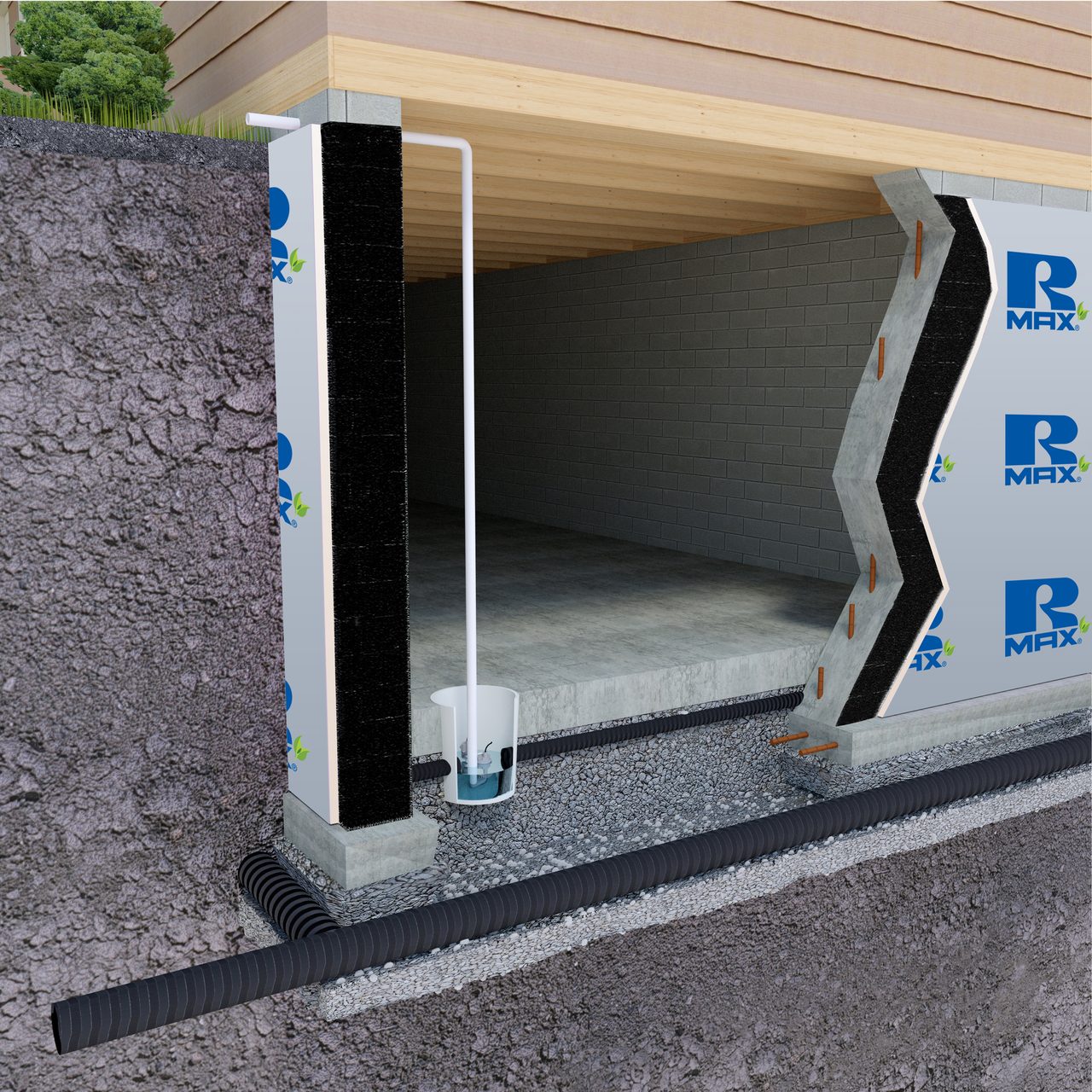

Below-grade exterior wall. Illustration courtesy of Rmax.

Polyiso is manufactured through a continuous lamination process in which the liquid raw materials that make up the foam formulation are mixed, causing a rapid chemical reaction that transforms them into a rigid and thermally stable polymeric closed-cell structure. This foam is laid between the two facer materials, and travel through a laminator allowing for initial curing. The laminator can be adjusted to produce different thickness boards, which are then trimmed and cut into various lengths, typically 4-foot by 8-foot size but can be customized for specific project requirements to fit engineering guidelines. These closed-cell, rigid foam boards are consistently rated as economical and easy to install.

[R-value measure 180 days]

Compressive Strength

In addition to its high thermal performance, polyiso is noted for its compressive strength. Below-grade, the soil that is backfilled against a foundation exerts lateral pressure on the foundation and below-grade walls. Soil weight presses downward and exerts lateral pressure. As an example, a well-drained soil can have a lateral load of 1,250psf at 10 foot depth below-grade and 1,875 psf at 15 feet below grade. Undrained soil systems can have a lateral load of 1,874 psf and 2,811 psf, respectively. Insulation or drainage materials without sufficient compressive strength are unable to resist this pressure and compress, reducing R-value and compromising drainage. Available in 16psi (2,300 psf), 20psi (2,880 psf) and 25psi (3,600 psf), polyiso board insulation has the compressive strength to resist soil pressures.

Water-Resistant Boards

Some builders may be hesitant to use polyiso below grade because they worry about damage to the facer during the backfill process. It is important to realize that, while the various facers do provide some added benefits to the boards, the foam itself is water-resistant because the chain reaction creates a closed cell that does not absorb water. As long as the concrete behind it is adequately waterproofed and the polyiso boards are properly installed with tight joints, its performance would not be compromised by incidental damage to the facer sustained during the installation process.

Use Above Frost Line

Polyiso insulation can also be used as part of a much shallower foundation, which saves on building costs. Building codes require that foundations extend below the local frost line. In cold climates, this can mean a foundation is more than 5 feet below-grade. However, polyiso insulation protects the foundation from freezing at shallower depths than the prescribed local frost line.

Though most builders think of polyiso as a product commonly used in low-slope commercial roofs, its consistently excellent performance has expanded its market share in applications on roofs and walls of all kinds in both commercial and residential projects. Its effective use in below-grade applications has an established history in Europe and is becoming increasingly more common here in the United States and Canada.

Polyiso manufacturers continue to rigorously test products by third-party independent laboratories for physical properties, fire and thermal performance as well as assess environmental impacts. Information is available from manufacturers of polyiso products. In addition, resources including such as industry-wide environmental product declarations, technical and product bulletins, building code resources, and educational materials, are available at http://polyiso.org, the website of PIMA, the Polyisocyanurate Insulation Manufacturers Association.

Benefits of Polyiso in Below Grade Applications:

- Eliminates thermal bridging, improving thermal efficiency

- Resists water absorption

- Reduces the risk of moisture infiltration

- Protects the waterproofing or damp-proofing from damage caused by backfill

- Keeps the wall warm, reducing the potential for condensation on the interior surface of the wall

- Keeps the wall warm, reducing the impacts of freeze-thaw structural damage

- Improves the durability of the foundation as it protects against moisture migration

- Offers consistent thermal resistance by eliminating thermal bridging

- Durable aluminum facer protects boards from backfill during construction

- Closed-cell foam

- Meets ASHRAE 90.1 below-grade water absorption requirements